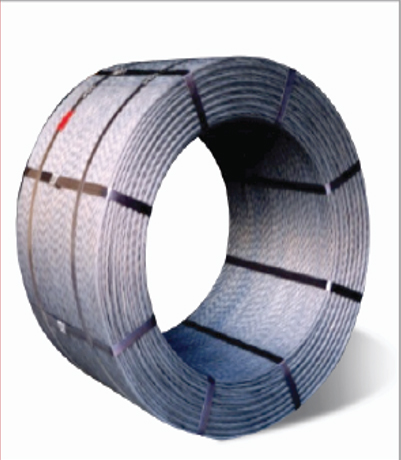

PC strand with 7 strands that are used in the areas such as bridge girder production, prefabricated construction elements, ground and mine anchorages, nuclear power stations, silo constructions, housing constructions are produced according to the ASTM, BS, EN, TSE and JIS standards.

Primary advantages provided by PC Strand:

- Having high tensile strength.

- Potential great prestressing in small edges.

- Less need for anchorage and application labor.

Advantages of the products with lower relaxation

- More tensile and yield strengths.

- Super durability against fatigue and corrosion.

- Consistent load elongation relation.

- Super straightening feature.

| ASTM A416 - SEVEN-WIRE UNCOATED STRAND - LRPC [LOW RELAXATION] | ||||||||||||||||||||||

| Diameter | Tensile Strength | Cross Sectional Area | Mass Per Metre | Strength | Extension | |||||||||||||||||

| (mm) | (in) | (Mpa) | (Grade) | (mm²) | (in²) | (g/m) | (lb/ 1000ft) | (kN) | (mm²) | (mm²) | (mm²) | |||||||||||

| 9.53 mm | 3/8" | 1725 | 250 | 51.61 | 0.080 | 405 | 272 | 89.0 | 20000 | 80.1 | 18000 | |||||||||||

| 1860 | 270 | 54.84 | 0.085 | 432 | 290 | 102.3 | 23000 | 92.1 | 20700 | |||||||||||||

| 12.70 mm | 1/2" | 1725 | 250 | 92.90 | 0.144 | 730 | 490 | 160.1 | 36000 | 144.1 | 32400 | |||||||||||

| 1860 | 270 | 98.71 | 0.153 | 775 | 520 | 183.7 | 41300 | 165.3 | 37170 | |||||||||||||

| 15.24 mm | 3/5" | 1725 | 250 | 139.35 | 0.216 | 1094 | 737 | 240.2 | 54000 | 216.2 | 48600 | |||||||||||

| 1860 | 270 | 140.00 | 0.217 | 1102 | 740 | 260.7 | 58600 | 234.6 | 52740 | |||||||||||||

| Standard | Nominal diameter | Standard | Elongation | Elongation | Relaxation Value | Theoretical weight per KM | ||

| mm | Mpa | KN | L0≥500mm | Initiate loads /maximum nominal load*100% | Relaxation Value 1000 hours no more than Class | Kg | ||

| GB/T 5224-2003 | 12.70 | 1860 | 166.0 | 3.5 | 70 | 2,5 | 775 | |

| 15.20 | 1860 | 260.0 | 3.5 | 80 | 4,5 | 1101 | ||

| 17.80 | 1860 | 353.0 | 3.5 | 80 | 4,5 | 1500 | ||

| ASTM416-06 | 11.11 | 1860 | 138 | 3.5 | 70 | 2,5 | 582 | |

| 12.70 | 1860 | 184 | 3.5 | 70 | 2,5 | 775 | ||

| 15.24 | 1860 | 261 | 3.5 | 70 | 2,5 | 1102 | ||

| B55896-1980 | 9.30 | 1860 | 92.0 | 3.5 | 80 | 2,5 | 408 | |

| 11.00 | 1860 | 125.0 | 3.5 | 80 | 2,5 | 557 | ||

| 12.50 | 1860 | 164.0 | 3.5 | 80 | 2,5 | 730 | ||

| 15.20 | 1860 | 232.0 | 3.5 | 80 | 2,5 | 1090 | ||

| B55896-1980 | 9.50 | 1860 | 86.6 | 3.5 | 70 | 2,5 | 430 | |

| 11.10 | 1860 | 117.0 | 3.5 | 70 | 2,5 | 582 | ||

| 12.70 | 1860 | 156.0 | 3.5 | 70 | 2,5 | 775 | ||

| 15.20 | 1860 | 220.0 | 3.5 | 70 | 4,5 | 1101 | ||

Wedge

| Model No. | Order Number | Wedge Type | Diameter Range | Tested Breaking Load | Wedge Lenght mm | Tooth Pitch mm | Weight Per Set |

| Nu.D-05WPR | PRW.05.00 | Pretensioning | 12,2 -12,7 | 172 kN | 47 | 1,0 | 178 g |

| Nu.D-06WPR | PRW.06.00 | 14,7 -15,3 | 257 kN | 166 g | |||

| Nu.D-62WPR | PRW.62.00 | 15,2 -15,8 | 276 kN | 162 g |

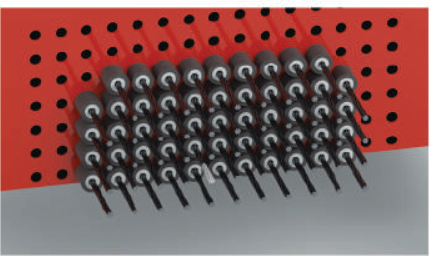

Barrel

| Especially Recommended for Presstressing Steel Diameter | 0,5” | 0,6” | 0,62” | ||

| 12,70 mm | 15,24 mm | 15,75 mm | |||

| Suitable Wedge Type | Pretensioning Wedge; Nu.D / WPR | ||||

| Possible Wedge Length | 47 mm | ||||

| Maximum Service Load | 160 - 220 kN | ||||

| Package - Quantity | 230 - 330 kN | ||||

| Ultimate Load | 16 Adet / Pcs | ||||

| Package - Dimensions | 250 x 250 x 75 (mm) | ||||

| Order No. (Without Wedges) | PG.07.01 .00 | ||||

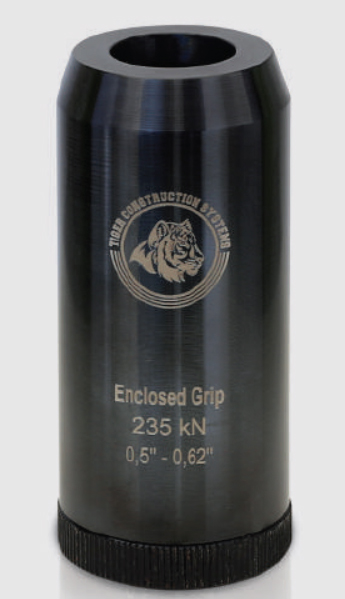

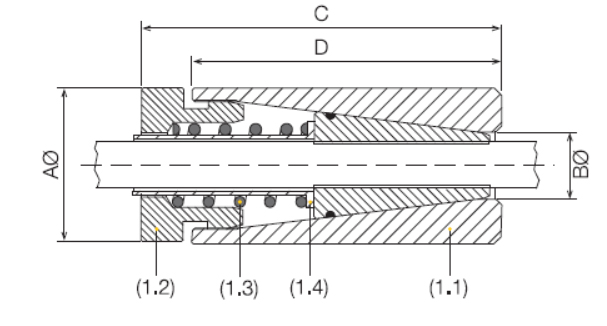

Enclosed Grip

| Especially Recommended for Presstressing Steel Diameter | 0,5” | 0,6” | 0,62” | ||

| 12,70 mm | 15,24 mm | 15,75 mm | |||

| Suitable Wedge Type | Pretensioning Wedge; Nu.D / WPR | ||||

| Possible Wedge Length | 47 mm | ||||

| Maximum Service Load | 160 - 220 kN | ||||

| Ultimate Load | 230 - 330 kN | ||||

| Package - Quantity | 8 Adet / Pcs | ||||

| Package - Dimensions | 250 x 250 x 75 (mm) | ||||

| Order No. (Without Wedges) | PG.07.01 .00 | ||||

| Order No. Barrel (1.1) | 07.1.01.00 | ||||

| Order No. Coupling Piece (1.2) | 07.1.02.00 | ||||

| Order No. Spring (1.3) | 07.1.03.00 | ||||

| Order No. Back Plate (1.4) | 07.1.04.00 | ||||

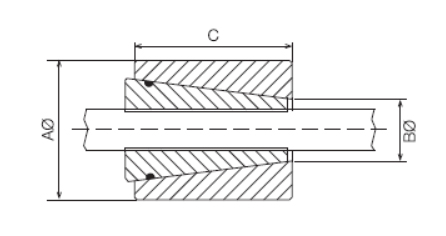

| Model No. | Diameter Range | Tested Breaking Load | A Ø mm | B Ø mm | C Ø mm | D Ø mm | Weight |

| AH-1P | 12,2 - 15,8 | 330 kN | 44,5 | 22,5 | 97 | 88 | 688g |

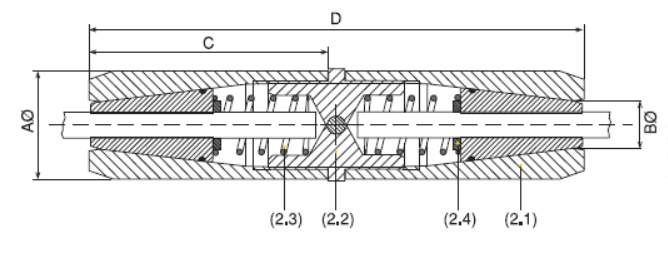

Coupler

| Especially Recommended for Presstressing Steel Diameter | 0,5” | 0,6” | 0,62” | ||

| 12,70 mm | 15,24 mm | 15,75 mm | |||

| Suitable Wedge Type | Pretensioning Wedge; Nu.D / WPR | ||||

| Possible Wedge Length | 47 mm | ||||

| Maximum Service Load | 160 - 220 kN | ||||

| Ultimate Load | 230 - 330 kN | ||||

| Package - Quantity | 4 Adel/ Pcs | ||||

| Package - Dimensions | 250 x 250 x 75 (mm) | ||||

| Order No. (Without Wedges) | CG.07.2.00 | ||||

| Order No. Barrel (2.1) | 07.2.01 .00 | ||||

| Order No. Coupling Piece (2.2) | 07.2.02 .00 | ||||

| Order No. Spring (2.3) | 07.2.03 .00 | ||||

| Order No. Back Plate (2.4) | 07.2.04 .00 | ||||

| Model No. | Diameter Range | Tested Breaking Load | A Ø mm | B Ø mm | C Ø mm | D Ø mm | Weight |

| CG-1 | 12,2 - 15,8 | 330 kN | 44,5 | 22,5 | 88 | 188 | 1398g |