Valve Bag Packing

Offers the most suitable solution for packaging granules, powder, fine powder, and grout products with medium and high densities.

General Features:

Bag Type: Kraft, PE, PP, vs.

Bags/Hour Capacity: 150/1200

Filling Weight: 10-50 Kg

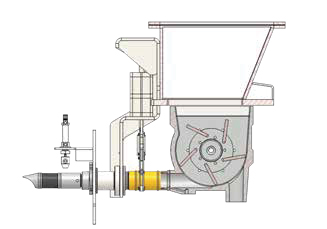

Impeller Type Valve Bag Filling Machine

Suitable for; Cement, cement sand, chemical mixtures, joint filler, gypsum, plaster, barite, miscellaneous chemicals.

Standart Specification:

- Automatic weighing unit with double speed filling and load-cell

- Easy change Hardox type impeller blade

- Heavy duty machine base

- Pneumatic control system

- Filter connection manifold (demand : ready for 1000m3/hour)

- Adjustable bag height

- Automatic cleaning system for filling nozzle

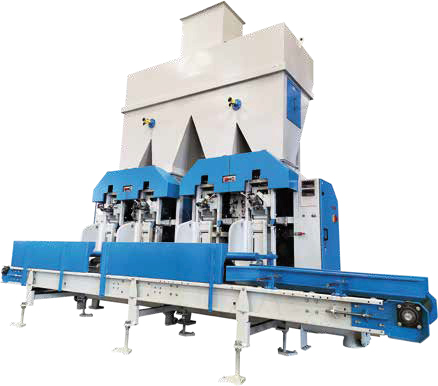

Air Type Valve Bag Filling Machine

Models with single, dual, triple and quad filling spouts are available according to capacity requirements.

Standart Specification:

- The blower is included the machine configuration

- Pneumatic controlled butterfly valve for product flow control

- Automatic weighing unit with double speed and load-cell

- Pneumatic control system

- Filter connection manifold (demand : ready for 1000m3/hour)

- Adjustable bag height

- Automatic cleaning system for filling nozzle

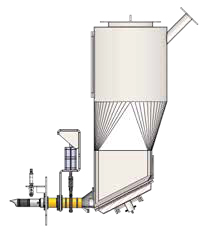

Rotary Filling Machine

Rotary filling machine are available in 4-6-8-10 spouts options. They are available in two types; air type is recommended for fine / lighter materials. Impeller type is recommended for regular products (such as cement, sand, binder).

General Features:

Type Options “ Filling Spouts” : 4, 6, 8 or 10 filling positions.

Impeller or Air Type

Bags/ Hour Capacity: Min 800 – Max 3000

Options

- All contacting surface product can produce AISI 304 stainless steel for food stuff

- Main product bunker and level sensor

- Bag evacuation conveyor

- Bag cleaning unit

- Bag presser

- Ultrasonic Sealing

- Jet-Pulse dust filters system