Polyester strap is an alternative product for steel strapping. Pet straps are designed for many different applications from light and medium duty even to heavy duty palletizing and unitizing applications as well as sharp edged packages.

Polypropylene (PP) was specially designed for light to medium heavy loads. Properties such as breaking strength, elasticity and tension loss are sufficient for many applications. It can be applied manually or with semi-automatic or fully automatic strapping machines. These straps are mostly used for packaging of food products, bundling of light metal tubes parcel packaging. PP Straps are environment friendly % 100 recyclable.

Hot Melt (Textile) Strap

Among the plastic straps, hot melt bonded relatively have the highest breaking strength. These straps are highly elastic and flexible and also they never get loose. Mostly used in aluminum industry, chemical industry, glass industry, stone brick industry, metal industry, wooden products and lumber industry, parcel packaging sectors and etc.

Composite Fiber Strap

These are our packaging straps made of high strength 100% industrial polyester fibres covered with polypropylene. Does not damage (scratch, crush, rust) the bonded surfaces. It does not require gloves and does not involve any risk of accident. It is suitable for sensitive surfaces that require high strength.

Strapping Machines

We are extremely capable to provide solution for any packaging and palletizing need. From 9 millimeters to 19 millimeters strap width, strapping machines can pull up to 5500 newtons of force that can keep any product together in safety.

Manual Strapping Machine

- Manual Strapping Machine

- Rechargeable Strapping Tools

- Semi Automatic Strapping Machine

- Plastic Buckle

- Strap Tensioner

- Metal Seal

- Plastic Edge Protector

- Phosphate Coated Buckle

- Strapping Dispenser

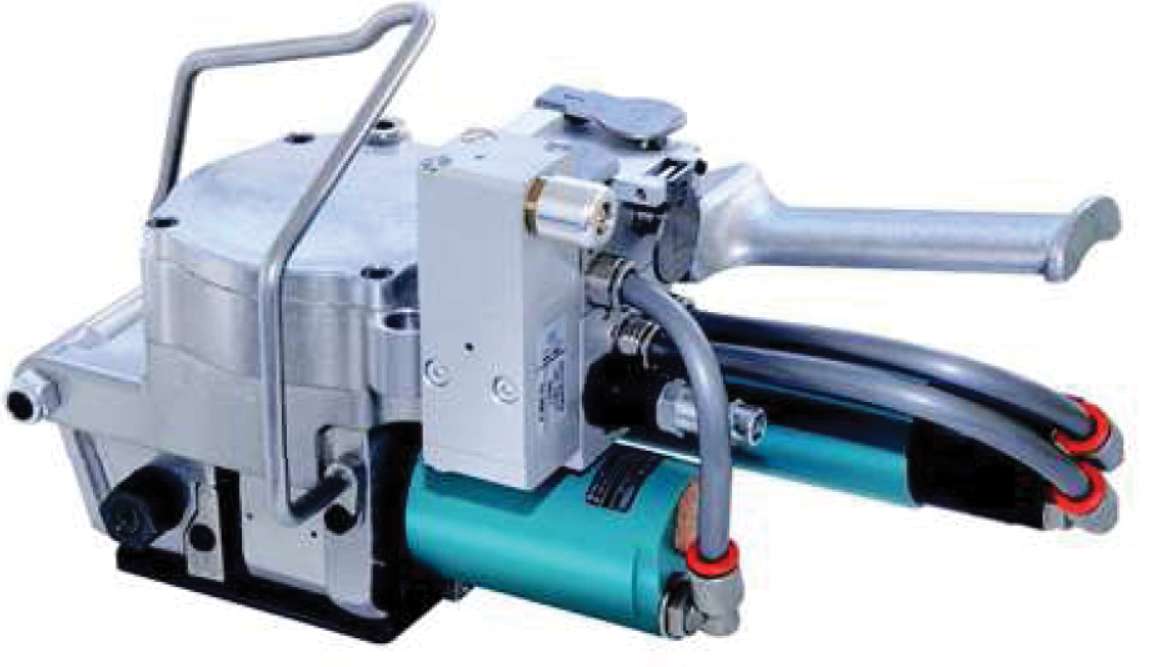

Electric Strapping Tool for PP and Polyester Strap With Vibration Sealing

We are extremely capable to provide solution for any packaging and palletizing need. From 9 millimeters to 19 millimeters strap width, strapping machines can pull up to 5500 newtons of force that can keep any product together in safety.

Electric Strapping Machine

| Dimensions | |

| Length | 290 mm • 11.4” |

| Width | 140 mm • 5.5” |

| Height | 165 mm • 6.5” |

| Weight | 3.6 Kgs • 7.9 lbs |

| Feeding | |

| Battery | 14.8V-2 A/h LI-PO |

| Performance | |

| Max. tension force | 2200N |

| Tensioning speed | 12mt/m |

| Sealing | Vibration sealing |

| Joint strength | 80% of breaking strength* |

| Gear ratio | - |

* variable according to strap type

Electric Strapping Machine

| Performance | |

| Max. tension force | 3500N - 6.5 bar - 92 psi |

| Tensioning speed | 9 mt/m |

| Sealing | Vibration sealing |

| Joint strength | 80% of breaking strength* |

| Gear ratio | - |

| ASTM A416 - SEVEN-WIRE UNCOATED STRAND - LRPC [LOW RELAXATION] | ||||||||||||||||||||||

| Diameter | Tensile Strength | Cross Sectional Area | Mass Per Metre | Strength | Extension | |||||||||||||||||

| (mm) | (in) | (Mpa) | (Grade) | (mm²) | (in²) | (g/m) | (lb/ 1000ft) | (kN) | (mm²) | (mm²) | (mm²) | |||||||||||

| 9.53 mm | 3/8" | 1725 | 250 | 51.61 | 0.080 | 405 | 272 | 89.0 | 20000 | 80.1 | 18000 | |||||||||||

| 1860 | 270 | 54.84 | 0.085 | 432 | 290 | 102.3 | 23000 | 92.1 | 20700 | |||||||||||||

| 12.70 mm | 1/2" | 1725 | 250 | 92.90 | 0.144 | 730 | 490 | 160.1 | 36000 | 144.1 | 32400 | |||||||||||

| 1860 | 270 | 98.71 | 0.153 | 775 | 520 | 183.7 | 41300 | 165.3 | 37170 | |||||||||||||

| 15.24 mm | 3/5" | 1725 | 250 | 139.35 | 0.216 | 1094 | 737 | 240.2 | 54000 | 216.2 | 48600 | |||||||||||

| 1860 | 270 | 140.00 | 0.217 | 1102 | 740 | 260.7 | 58600 | 234.6 | 52740 | |||||||||||||

| Dimensions | |

| Length | 300 mm • 11” |

| Width | 150 mm • 6” |

| Height | 175 mm • 6.9” |

| Weight | 5.1 Kgs • 11.2 lbs |

* variable according to strap type